Fasteners and Machining: Enhancing the Production Process

Fasteners and Machining: Enhancing the Production Process

Blog Article

Browsing the World of Fasteners and Machining: Techniques for Precision and Rate

In the elaborate world of bolts and machining, the mission for accuracy and speed is a perpetual obstacle that demands careful attention to information and tactical preparation. From understanding the varied array of bolt types to picking ideal products that can endure strenuous demands, each step in the procedure plays a pivotal function in accomplishing the wanted end result.

Understanding Bolt Kind

When selecting bolts for a project, understanding the different types available is essential for making certain ideal efficiency and reliability. Fasteners come in a vast variety of kinds, each developed for specific applications and needs. Bolts are used with nuts to hold products together, while screws are flexible bolts that can be used with or without a nut, relying on the application. Nuts, on the other hand, are inside threaded bolts that companion with screws or screws, giving a protected hold. Washing machines are vital for dispersing the tons of the bolt and preventing damage to the product being attached. In addition, rivets are permanent bolts that are suitable for applications where disassembly is not needed. Recognizing the distinctions between these bolt types is important for choosing the right one for the work, guaranteeing that the connection is strong, resilient, and reliable. By picking the ideal bolt kind, you can optimize the efficiency and longevity of your project - Fasteners and Machining.

Selecting the Right Products

Recognizing the value of selecting the ideal materials is vital in making sure the ideal performance and reliability of the chosen bolt types talked about formerly. When it involves bolts and machining applications, the product choice plays a crucial role in identifying the general strength, resilience, corrosion resistance, and compatibility with the intended environment. Different products offer varying properties that can considerably impact the efficiency of the bolts.

Common products made use of for bolts include steel, stainless steel, brass, titanium, and aluminum, each having its special toughness and weaknesses. Steel is renowned for its high strength and longevity, making it appropriate for a broad array of applications. Choosing the best material entails considering factors such as strength requirements, environmental problems, and budget plan constraints to ensure the preferred performance and longevity of the bolts.

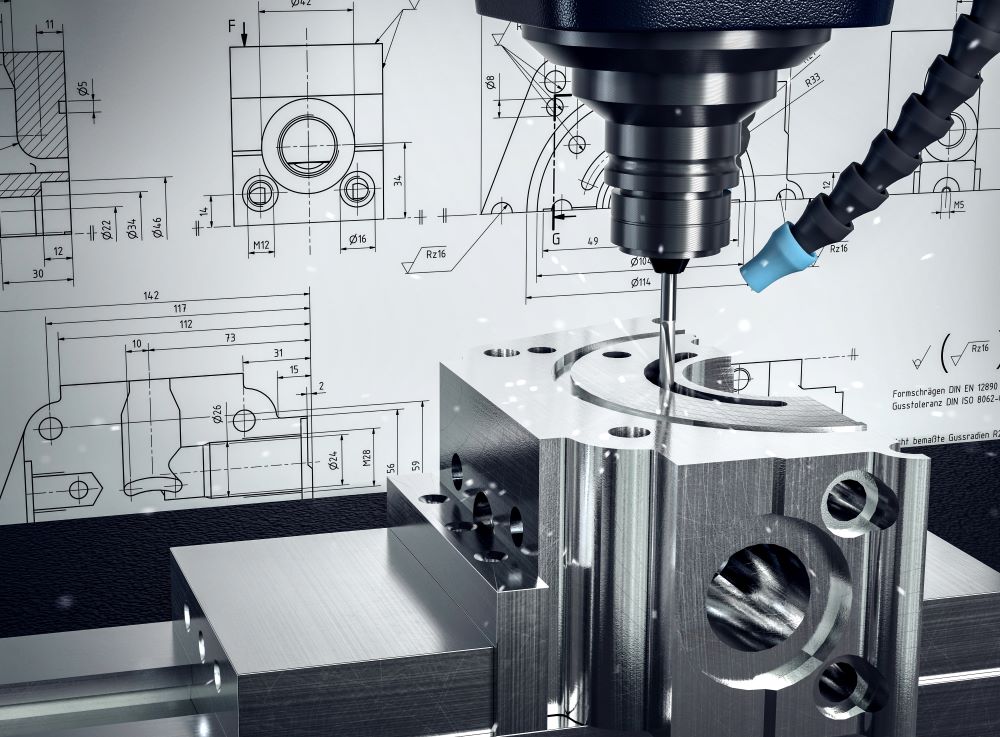

Accuracy Machining Techniques

In addition to CNC machining, various other accuracy methods like grinding, turning, milling, and drilling that site play important duties in bolt production. Grinding assists attain fine surface coatings and limited dimensional tolerances, while turning is frequently used to create round elements with accurate sizes. Milling and exploration operations are essential for shaping and creating holes in bolts, ensuring they fulfill specific requirements and feature appropriately.

Enhancing Rate and Efficiency

To optimize fastener manufacturing processes, it is necessary to streamline procedures and execute reliable methods that enhance accuracy machining techniques. One key method for improving rate and effectiveness is the application of lean manufacturing principles. By decreasing waste and concentrating on continual renovation, lean methods help remove traffic jams and maximize process. In addition, purchasing automation modern technologies can dramatically increase production speed. Automated systems can handle recurring tasks with precision and rate, permitting employees to concentrate on more complicated and value-added activities. Adopting Just-In-Time (JIT) inventory administration can additionally boost performance by ensuring that the right products are available at the best time, reducing excess supply and reducing lead times. Promoting a society of partnership and communication among straight from the source team participants can improve total performance by advertising transparency, analytic, and development. By combining these strategies, makers can attain a balance in between rate and accuracy, ultimately boosting their affordable edge in the fastener sector.

Quality Control Procedures

Carrying out strenuous high quality control procedures is critical in guaranteeing the reliability and consistency of fastener items in the manufacturing procedure. Fasteners and Machining. Quality control actions include various phases, starting from the option of raw products to the final evaluation of the finished fasteners. This entails assessing elements such as product make-up, stamina, and sturdiness to ensure that the bolts fulfill market standards.

Routine calibration of tools and machinery is crucial to keep uniformity in manufacturing and guarantee that fasteners fulfill the necessary tolerances. Executing strict procedures for recognizing and addressing non-conformities or issues is vital in protecting against substandard items from going into the market. By developing a detailed top quality control framework, suppliers can promote the reputation of their brand name click here for info and deliver bolts that meet the highest possible standards of efficiency and toughness.

Verdict

In the elaborate realm of fasteners and machining, the mission for precision and speed is a continuous challenge that requires meticulous interest to information and strategic planning. When it comes to bolts and machining applications, the material selection plays an essential function in identifying the total stamina, resilience, corrosion resistance, and compatibility with the intended setting. Accuracy machining involves numerous sophisticated methods that make certain the limited tolerances and specifications needed for bolts.In enhancement to CNC machining, other precision strategies like grinding, turning, milling, and exploration play crucial duties in fastener manufacturing.To optimize bolt manufacturing procedures, it is crucial to simplify operations and apply effective techniques that complement precision machining strategies.

Report this page